Kia Australia announces specifications and pricing of 2022 EV6

Starting from $67,990 MSRP, all EV6s receive the 77.4 kWh battery as standard, and offer 484- 528 kilometres of range.

Kia’s EV6 GT (left, centre) and EV6 Air (right) Images: Kia Australia

EV6 Air rear wheel drive (RWD) priced from $67,990 (MSRP) - 168kW/350Nm, 0-100km/h in 7.3 seconds with 528km WLTP range

EV6 GT-Line RWD priced from $74,990 - 168kW/350Nm, 0-100km/h in 7.3 seconds with 504km WLTP range

EV6 GT-Line all wheel drive (AWD) priced from $82,990 - 239kW/605Nm, 0-100km/h in 5.2 seconds with 484km WLTP range

Kia has used its major sponsorship of the Australian Open to launch the flagship EV6 electric vehicle. priced from $67,990 in rear wheel drive entry-level guise, the EV6 undercuts a number of its competitors on price, including the Hyundai IONIQ 5 2WD based on the same vehicle platform. The Hyundai starts from $71,900, with a slightly smaller battery than the Kia, albeit with more standard equipment.

The EV6 debuts Kia’s evolution of its “Tiger face” styling; a digital tiger face if you will. Karim Habib, head of Kia design announced last year that while future electric products (including the EV6) would keep elements of the brand’s signature look, he said “What you see [on the new EV6] is what we like to think of as the ‘digital tiger face’. As we move away from the grille that is really there to be an air intake, it’s more how to combine all the elements in the front and how to create an identity in the front that is based in the tiger nose.”

The EV6 takes a complete different design direction to Hyundai's parametric pixel language found on the IONIQ 5; a more sculpted, sporty and athletic presence highlight’s the brand’s performance ambitions.

The EV6 comes standard in Australia with SK Innovation’s 77.4 kWh battery system, trumping Hyundai’s 72.6 kWh battery (just). Those extra kilowatt hours translate to an additional 77km of range though, and with 528km WLTP range in rear wheel drive guise, the EV6 becomes a member of the 500km club, alongside Tesla’s Model 3 LR, Model S Plaid, and upcoming BMW iX and Mercedes-Benz EQS.

The Kia EV6 GT-Line rear features a striking LED light signature.

What comes as standard in the EV6?

Standard Equipment is good, and broadly follows Kia’s thinking from previous electric models. The rear wheel drive EV6 receives 19” alloy wheels, solar glass with an acoustic film windscreen, flush door handles (not auto folding), cloth/faux leather seats, twin 12.3” curved displays, wireless phone charging, and a crucial feature missing from the IONIQ 5 down under, an interior Vehicle to Load (V2L) connector, allowing EV6 owners to plug any household device into the car. Happily, Kia Australia has listened to us (and other motoring writers) and included the majority of its safety and assistance systems as standard in both EV6 variants. There’s autonomous emergency braking, blind spot detection, lane keep assist, smart cruise control with stop and go and more.

The Kia EV6 GT Line Interior.

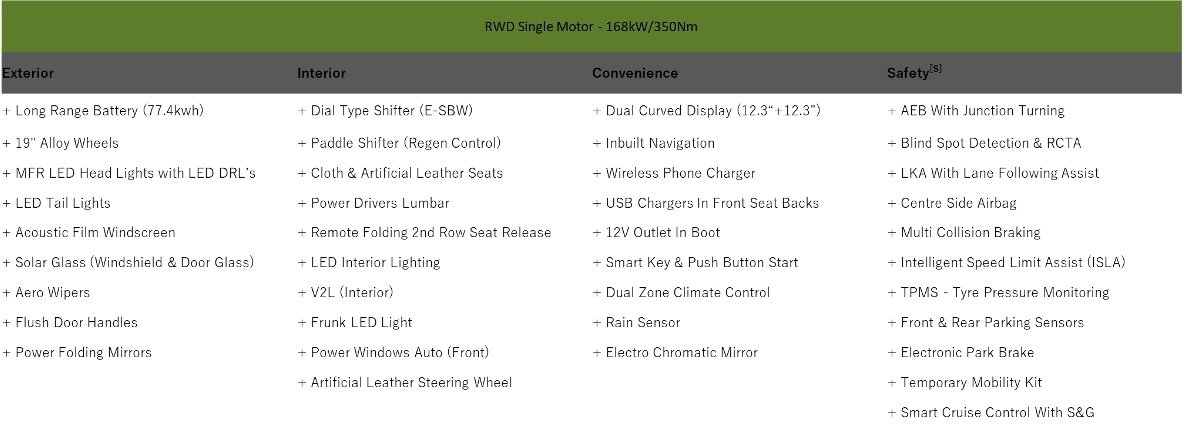

Kia EV6 rear wheel drive single motor standard equipment.

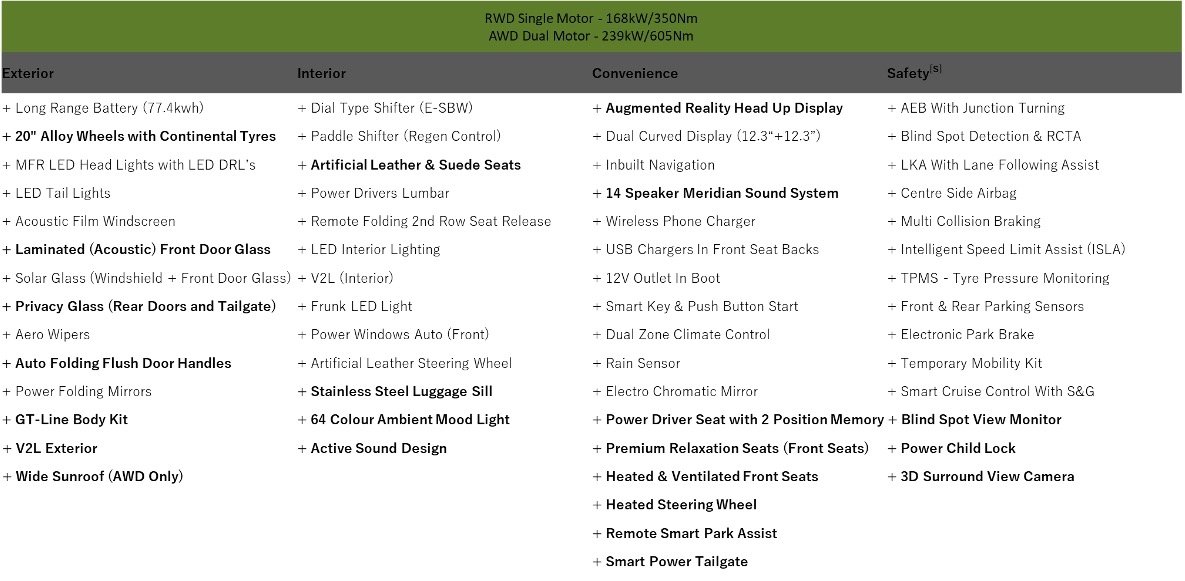

The EV6 AWD Dual Motor receives a raft of additional equipment as standard, including bigger 20-inch alloy wheels (aesthetics over range), laminated front door glass and privacy glass, an exterior body kit, exterior V2L, alcantara seat inserts, ambient lighting, a 14 speaker Meridian sound system, powered seats with heating and cooling, a powered tailgate, and 3D surround view camera.

Kia EV6 all wheel drive additional standard equipment highlighted in bold.

Kia EV6 Colours and trim choices

The Kia EV6 Air will be available in six colours, and the EV6 GT-Line will be available in five colours. The hero Moonscape matte colour exclusive to GT-Line, and is also a first for the Kia range. At this stage it appears interior colour choices are limited to…black. If you want a lighter interior, stick with Hyundai’s IONIQ 5.

Kia EV6 Australian colour options.

Battery and Technology

Like its Hyundai IONIQ 5 cousin, the EV6 is blessed with an 800 volt electrical system, meaning that a theoretical 233 kW peak charging rate can be achieved (although we’ve only ever seen this briefly in our two weeks with the IONIQ 5) replenishing 100km of range in 4 minutes, or 10-80 percent battery state of charge in 16 minutes.

An 11kW AC charger will see a 0-100 percent charge take around 7 hours and 45 minutes.

Kia EV6 fast charging curve. Image: Fastned

So how can I buy an EV6?

Errr, here’s the catch. With such limited supply due to global constraints, and the fact that Australia is just a small market, the EV6 is already sold out for 2022. 500 units have been allocated for Australia, and are already spoken for, but we understand Kia Australia is working hard to secure additional units for 2022/2023.

More information will be provided on the EV6 range in Australia after the car’s late-February media launch; we also hope to find out more about the performance eGT EV6 which should launch late in 2022.

Mercedes-Benz announces electrification plan, EV and battery rollout, end of internal combustion vehicles

Mercedes-Benz has announced an end to its internal combustion-engined product offerings, moving towards a range of electric-only vehicles by 2030. Mercedes-Benz will cease the development and release of internal combustion vehicle architectures from 2025, launching three electric-only platforms in the same year.

Mercedes-Benz has announced an end to its internal combustion-engined product offerings, moving towards a range of electric-only vehicles by 2030. The caveat provided by the company is that zero-emissions vehicles will prevail “where market conditions allow”, presumably giving the automaker a guilt-free emissions pass in markets where charging infrastructure and EV uptake is yet to develop.

Mercedes-Benz will cease the development and release of internal combustion vehicle architectures from 2025, and will launch three electric-only platforms in the same year. According to the company, customers will be able to choose an all-electric alternative for every model in the Mercedes-Benz range, and that “Mercedes-Benz intends to manage this accelerated transformation while sticking to its profitability targets.”

Ola Källenius, CEO of Daimler AG and Mercedes-Benz AG said in a media statement that "The EV shift is picking up speed - especially in the luxury segment, where Mercedes-Benz belongs. The tipping point is getting closer and we will be ready as markets switch to electric-only by the end of this decade," "This step marks a profound reallocation of capital. By managing this faster transformation while safeguarding our profitability targets, we will ensure the enduring success of Mercedes-Benz. Thanks to our highly qualified and motivated workforce, I am convinced that we will be successful in this exciting new era."

Ola Källenius, CEO of Daimler AG and Mercedes-Benz AG with the Mercedes-Benz EQ range.

Mercedes-Benz’s Future Product Line-Up

Let’s look at the above image and get a sense of where the brand is heading this decade. We’re already familiar with the upcoming EQS luxo-barge next to Ola Källenius, and pictured to its right is the soon-to-be-revealed EQE sedan. Both vehicles are based on Mercedes-Benz’s Electric Vehicle Architecture (EVA) modular platform. Behind them, from left to right, we have the GLB crossover, and the currently on sale EQC and EQA crossovers. In the third row, a mysterious crossover —likely the EQS SUV— sits just ahead of the EQV.

Mercedes-Benz revealed its subbrands including AMG, Maybach and G-Class —made infamous in the 2010s as a symbol of gas-guzzling excess— will go electric. The EQS SUV will be the first vehicle in the lineup to receive the Maybach work-over, as teased in this image below.

The Mercedes-Benz EQS SUV Maybach. Image: Mercedes-Benz

All subbrands to go electric. Images: Mercedes-Benz.

Brand new electric platforms from 2025

Three electric-only architectures will be launched in 2025:

MB.EA will cover all medium to large size passenger cars, establishing a scalable modular system as the electric backbone for the future EV portfolio.

AMG.EA will be a dedicated performance electric vehicle platform addressing technology and performance oriented Mercedes-AMG customers.

VAN.EA ushers in a new era for purpose made electric vans and Light Commercial Vehicles, which will contribute to emission free transportation and cities in the future.

Manufacturing and battery cell demands

The upcoming mercedes-Benz EQB.

Mercedes-Benz plans to install battery cell capacity of more than 200 Gigawatt hours with partners, and sets its sights on eight Gigafactories to support this product rollout. The company will develop new partnerships for R&D and production of battery cells in Europe.

Following Tesla’s lead and in an attempt to reduce the bureaucracy and cost of development for legacy automakers, Mercedes-Benz is reorganizing its powertrain activities to put planning, development, purchasing and production under one roof. The company claims this will deepen the level of vertical integration in manufacturing and development and electric drive technology.

Mercedes-Benz’s next-generation batteries will debut in 2025 and will be highly standardized, and suitable for use across more than 90 percent of all Mercedes-Benz cars and vans according to the automaker. The company intends to focus battery cell and module manufacturing in Europe, keeping the supply chain close to home. It will work with technology partners across Europe such as SilaNano to further increase energy density in batteries through silicon- carbon composite anodes.

Mercedes-Benz is also developing solid-state technology, with an aim to create batteries with even higher energy density and safety. The company is already trialling Citaro buses with solid-state batteries.

EV Brief’s Take

This is all great news in our view. After a general reluctance to commit to electrification from Germany’s big automakers, Mercedes-Benz is officially going “all in”. Massive investment in capital works, battery gigafactories, and cell R&D, as well as ensuring reduced emissions and CO2 neutrality from the production process will allow the brand to get ahead of strict EU emissions regulations, while ensuring future commercial viability.

Streamlining its business through centralised production, common battery modules and shared platform architecture will not only lead to positive business outcomes and an increased return on investment, but it should also bring with it faster product rollout timeframes, and a greater diversity of product offerings.

Source: Mercedes-Benz

The Mercedes-Benz EQS.

Mercedes-Benz EQS sedan enters series production ahead of summer 2021 launch

The Mercedes-Benz EQS has entered series production at the company’s Factory 56 in Sindelfingen, Germany, alongside Mercedes-Benz S-Class and Mercedes-Maybach models.

Mercedes-Benz board members and executives celebrating the start of EQS series production. Image: Daimler

The Mercedes-Benz EQS has entered series production at the company’s Factory 56 in Sindelfingen, Germany, alongside Mercedes-Benz S-Class and Mercedes-Maybach models. The production facility is the result of over 730 million Euros invested, as Mercedes-Benz looks to rolling out its electrification strategy, and reducing its environmental footprint.

Factory 56 will be completely CO₂-neutral, thanks in part to a rooftop photovoltaic system and energy storage system based on reused vehicle batteries. Mercedes-Benz plans to use Factory 56 as an environmentally friendly manufacturing blueprint to transfer to its other vehicle plants worldwide.

Mercedes-Benz claims to have reached new levels of efficiency in the assembly process, due to high levels of digitisation and an MO360 digital ecosystem that focuses on providing the best possible support to its 1,500+ workers at Factory 56.

According to Michael Bauer, Site Manager and Head of Production of Mercedes-Benz Sindelfingen Plant, "With the EQS in our portfolio, we are once again proving the future viability of the Sindelfingen site: Here tradition is combined with a new understanding of innovation and sustainability. Thanks to our highly competent team, we have successfully completed the start of production of the EQS at the Mercedes-Benz Sindelfingen plant."

The EQS is set for a summer 2021 launch in Europe and North America, with other markets to follow late in 2021-22. Read more on the EQS in our launch preview.

Factory 56 at the Mercedes-Benz Sindelfingen plant. Image: Daimler.

Mercedes Benz EQS exterior revealed - meet Stuttgart's first EV luxury sedan

The Mercedes Benz EQS is an important vehicle for the Stuttgart automaker. 120 years after the trademark ‘Mercedes’ was registered by Daimler-Motoren-Gesellschaft in 1901, we now have an all-electric sedan that is designed to ensure not only that the company remains the king of luxury motoring, but also the relevance and profitability in a world of strict emissions legislation, and dwindling resources.

2021 Mercedes Benz EQS debuts ‘sensual purity’ design language, 770 km range from 107.8 kwh battery

Mercedes Benz EQS 450+

single permanent magnet synchronous motor, rear wheel drive

245 kW (333 PS) / 568 Nm (418 lb ft), WLTP combined energy consumption 20.4-15.7kWh/100 km, range not stated

90 kWh nickel, manganese cobalt (NMC) modular battery, pouch cell design with 400V architecture, 200 kW DC fast charging

Mercedes Benz EQS 580 4MATIC

front and rear permanent magnet synchronous motors, all wheel drive

385 kW (523 PS) / 855 Nm (630 lb ft), WLTP combined energy consumption 21.8-17.4 kWh/100 km, range up to 770 km (478 miles)

107.8 kWh NMC modular battery, hard case cell design with 400V architecture, 200 kW DC fast charging

The Mercedes Benz EQS is an important vehicle for the Stuttgart automaker. 120 years after the trademark ‘Mercedes’ was registered by Daimler-Motoren-Gesellschaft in 1901, we now have an all-electric sedan that is designed to ensure not only that the company remains the king of luxury motoring, but also the relevance and profitability in a world of strict emissions legislation, and dwindling resources.

We’ve already covered the technical details, interior and Hyperscreen quite recently, so let’s look at what Mercedes-Benz has revealed today.

Exterior Design

It’s nice to finally be able to put a face to the EQS name. Designing such a flagship vehicle must be rather difficult, and on the whole, Gorden Wagener and his team must be congratulated. The EQS is a balance of progressive style and refined, familiar luxury. It’s a vehicle that has to outline the brand’s future direction, while still appealing to the S-Class buyer.

There are some odd angles however; soft, sloping front and rear are a result of function over form no doubt. With a drag coefficient of 0.2 cd, Mercedes Benz claims the EQS is the slipperiest sedan in the world.

Mercedes Benz states that the design philosophy behind the EQS can be defined as ‘Sensual Purity’ and that this is realised through clear, uncomplicated surfaces, curves and surface-emphasising modelling. It’s certainly not a fussy design, but will it appeal to buyers looking for a certain level of aggression and sportiness? Perhaps we’ll have to wait for an AMG version to find out.

The short front end and cab-forward look is almost the antithesis of the long-hooded luxo-barge look we’ve come to expect from this segment over the last few decades. The front end is handsome, if considerably more restrained than the EQS concept car. The black ‘grille’ on the front of the EQS is available with a Mercedes star pattern, if customers choose the AMG Line Exterior or Electric Art Exterior.

Frameless, coupé-like doors and a high, arched beltline draw the eye down the body to the rear of the EQS. Flush doorhandles aid aerodynamics, and provide a clean side profile view. The glasshouse is accentuated with chrome, and a two tone paint scheme is available.

Broad, generous surfaces, reduced join in body panels create an almost seamless transition between glass and bodywork at the rear. The rear tail light assembly is a broad, futuristic swoop of red, accentuating the width and hinting of the power within the EQS. 19-22 inch wheels are available, and the three exterior package inclusions are listed below:

Our favourite view of the EQS sedan

In our eyes, the most attractive angle of the EQS is a slightly raised and offset front three quarter view. The body is made of aluminium to keep weight down, and the front hood (bonnet) is of a clamshell design. Frunk fans will be disappointed to learn there’s no front storage compartment, but there’s ample space in the passenger compartment and rear trunk, with 610 litres of cargo capacity.

At 5.2 metres long with a 3.2 metre wheelbase — 106mm longer than the W223 S-Class — the EQS is a big car. The EQS 450 weighs in at 2480 kg (5467 lb), while the EQS 580 is 2585 kg (5,698 lb).

Mercedes Benz is expected to release an AMG performance variant of the EQS in the future, as well as a cheaper version with a smaller battery capacity. Europe, the UK and North America should see the EQS launch in the second half of 2021, while it’s expected that Mercedes-Benz Australia will bring the EQS down under in December 2021/January 2022.

You can read more of our coverage on the technical aspects of the EQS here, and view more galleries below:

2021 Mercedes Benz EQS exterior gallery

2021 Mercedes Benz EQS interior gallery

Mercedes Benz EQS and Audi Q4 electric vehicles to debut this week

It’s a big week for German manufacturers Mercedes Benz and Audi, as the automakers from Stuttgart and Ingolstadt premiere two important electric vehicles in their respective line ups.

It’s a big week for German manufacturers Mercedes Benz and Audi, as the automakers from Stuttgart and Ingolstadt premiere two important electric vehicles in their respective line ups.

Mercedes Benz will be unveiling their flagship electric vehicle, the EQS sedan on April 15, and the company has teased some technical details and some images, we’re still very keen to see the vehicle in all its glory.

You can watch the livestream below at the following times:

15/4/21 - 6pm CEST

4/15/21 - 10am PDT

16/4/21 - 2am AEST

Audi’s Q4 E-Tron is an important vehicle for the Ingolstadt manufacturer, as it is the first mid-size SUV based on the new modular electric MEB architecture. Again, the automaker has teased plenty of information and images of the Q4 E-Tron, but we can’t wait to see final specifications, colour and trim options. The Q4 E-Tron will go head-to-head with BMW’s iX3 and Tesla’s Model Y, but also with new competitors in the compact to mid-size SUV category. This is the first time South Korean manufacturers are competing in the premium segment with genuinely innovative, class-leading vehicles in the form of Kia’s EV6 and Hyundai’s Ioniq 5 , and we would expect many buyers to be seriously cross-shopping these vehicles when they hit the market.

Audi’s Q4 E-Tron livestream is also available below at the following times:

15/4/21 - 7pm CEST

4/15/21 - 11am PDT

16/4/21 - 3am AEST

Mercedes-Benz releases technical details of electric EQS sedan ahead of April 15 launch

Following the recent reveal of the Mercedes Benz EQS interior, we now have a full suite of technical details for the S-Class segment EV from the German automaker. Set to arrive in three variants, the EQS sedan will be a technological tour-de-force based on the automaker's dedicated EV architecture dubbed EVA

Mercedes-Benz EQS 580 4MATIC flagship to offer 770km range, 385kW power

Following the recent reveal of the Mercedes Benz EQS interior, we now have a full suite of technical details for the S-Class segment EV from the German automaker. Set to arrive in three variants, the EQS sedan will be a technological tour-de-force based on the automaker's dedicated EV architecture dubbed EVA, with an aerodynamic drag coefficient of 0.20cd (Tesla’s revised Model S promises a drag coefficient of 0.208cd), rear and all wheel drive options, sophisticated thermal management, and two battery options with net usable capacities of 90 kW and 107.8 kW. Let’s take a look at the range:

Mercedes Benz EQS 450+

single permanent magnet synchronous motor, rear wheel drive

245 kW (333 PS) / 568 Nm (418 lb ft), WLTP combined energy consumption 20.4-15.7kWh/100 km, range not stated

90 kWh nickel, manganese cobalt (NMC) modular battery, pouch cell design with 400V architecture, 200 kW DC fast charging

Mercedes Benz EQS 580 4MATIC

front and rear permanent magnet synchronous motors, all wheel drive

385 kW (523 PS) / 855 Nm (630 lb ft), WLTP combined energy consumption 21.8-17.4 kWh/100 km, range up to 770 km (478 miles)

107.8 kWh NMC modular battery, hard case cell design with 400V architecture, 200 kW DC fast charging

Is there anything special about the technology in the EQS?

In typical Mercedes Benz fashion, the press kit is a weighty tome. The largest battery available is a whopping 107.8 kWh, good for a claimed 770 kilometres (478 miles) of range on the WLTP combined cycle. Mercedes-Benz states the battery management system is designed for over the air updates, and that the batteries’ cell chemistry has been revised to reduce cobalt use, with the optimised active material constituting nickel, cobalt and manganese in a ratio of 8:1:1.

AC charging is available up to 22 kW, and DC charging can pump 200 kW into the EQS, good for 300 kilometres (186 miles) of charge in 15 minutes.

In terms of the drivetrain, Mercedes-Benz has worked with Bosch to develop synchronous motors for the EQS, unlike the asynchronous type found in the EQC. This means that the speed of the stator's magnetic field is equal to the motor's rotor speed, eliminating slip, and providing greater refinement, precision and efficiency. The motor on the rear axle features six-phase operation with two windings of three phases each, and stators with pull-in winding.

Mercedes-Benz claims a particularly strong magnetic field, improving energy efficiency, performance and reducing space in these new motors. The 4MATIC all wheel drive system continuously distributes the drive torques between the front and rear axles.

Braking recuperation is available, with drivers able to select from three stages. The recuperation output is up to 290 kW, with the ability to brake to a stop.

How smart is the EQS?

Tesla’s navigation route guidance has the ability to accurately calculate projected energy consumption versus real time consumption to your destination based on driving inputs, traffic and topography has always been considered industry leading. Mercedes-Benz will be introducing Navigation with Electric Intelligence on the EQS, which promises to calculate routes based on projected energy demand including topography of route, ambient temperature, energy consumers and more, as well as responding dynamically to congestion and changes in energy demand.

Mercedes-Benz promises smart navigation on the EQS.

Critically, the charging process must be simple for the EQS. Mercedes-Benz will be attempting to lure current S-Class owners into their flagship EV, and will also be looking to make conquest sales from the likes of Tesla, Porsche and BMW. It is critical that the charging process requires minimal effort for EQS owners, and Mercedes-Benz is promising a plug-and-charge service at European Ionity chargers where the vehicle and charger will automatically perform a handshake and sort out payment. It’s expected that United States EQS owners will have access to the Electrify America (EA) DC fast charging network, but it’s imperative that this flagship vehicle avoid charging issues seen by many on the Electrify America network.

The Mercedes-Benz EQS will be revealed in full on April 15.

Source: Mercedes-Benz

Mercedes-Benz reveals EQS EV interior before worldwide debut on April 15th

Mercedes-Benz has shown us the production ready interior of its upcoming EQS sedan, and its a thing of illuminated beauty if timber, glass and OLEDs are your thing. The EQS is the flagship vehicle for Mercedes-Benz’ EQ brand—literally the S-Class of the electric world—so you can expect that the designers have gone all out.

Mercedes-Benz has shown us the production ready interior of its upcoming EQS sedan, and its a thing of illuminated beauty if timber, glass and OLEDs are your thing. The EQS is the flagship vehicle for Mercedes-Benz’ EQ brand—literally the S-Class of the electric world—so you can expect that the designers have gone all out.

The MBUX Hyperscreen is the (optional) pièce de résistance, combining all features of the drivers’ instrument panel, dashboard and infotainment into a single glass panel. Mercedes-Benz likes to reference historical details, and the thin silver shadow frame around the screen, combined with the single ventilation band and a narrow leather frame are reminiscent of classic instrument panels according to the automaker.

If one doesn’t option the Hyperscreen, the interior looks quite similar to the latest W223 S-Class. with a single, vertically mounted touchscreen. The EQS is set to debut on April 15, before going on sale in July/August 2021. Scroll down for 10 interesting facts about the interior of the EQS:

The EQS interior with hyperscreen and floating centre console.

10 interesting facts about the interior of the EQS:

With the MBUX Hyperscreen, multiple displays merge seamlessly to create an impressive curved screen band over 141 centimetres wide. The area perceived by the occupants measures 2432.11 sq. cm.

The large glass covering the MBUX Hyperscreen is curved in three dimensions in a moulding process at temperatures of approx. 650°C.

The HEPA filter (High Efficiency Particulate Air) as part of the optional equipment ENERGIZING AIR CONTROL Plus cleans the incoming outside air at its very high filtration level. Over 99.65 percent of particles of all sizes are eliminated, and the adsorption area is equivalent to about 150 football fields.

The key applications are always offered on the top level in the field of vision, depending on the situation and context, as part of Mercedes’ “zero-layer design”.

The "Mercedes-Benz pattern" is used in several places in the EQS interior such as on the backlit trim elements or on the passenger display as a digital decorative image. It is an abstracted, three-dimensional star pattern based on an early trademark of the Daimler Motorengesellschaft.

The EQS comes with the two soundscapes Silver Waves and Vivid Flux, and they can be selected or switched off as sound experiences on the central display. The algorithms and sounds for the sound design are created in-house at Mercedes-EQ by physicists, sound designers, media designers and mechatronics specialists.

Mercedes-Benz is showcasing its modern, leather-free material for the interior, NEOTEX. According to the company, it “combines the look of nubuck leather and high-tech neoprene”. There are eight coordinated colour combinations in the interior.

More than 40 new inventions have found their way into EQS. In addition, 20 design applications protect the design of the vehicle.

The design of the door panels borrows from the interior design of modern living spaces. Doors and their centre panels emerge from behind the MBUX Hyperscreen to span the space. A surface-mounted modular body floats like a sideboard in front of the door panel.

ENERGISING COMFORT features three programmes—Forest Glade, Sounds of the Sea and Summer Rain—which provide an immersive and realistic on-board sound experience. These calming sounds were created in consultation with the acoustic ecologist Gordon Hempton.

Mercedes-Benz Reveals Unique Hyperscreen for Upcoming EQS EV

Mercedes-Benz is premiering its new MBUX (Mercedes-Benz User Experience) multimedia interface, which will debut in the upcoming EQS battery electric sedan. Dubbed MBUX Hyperscreen, the digital experience promises to transform how we interact with the vehicle, and provide a “wow” effect according to Mercedes-Benz.

The new MBUX Hyperscreen comprises three individual OLED displays underneath a single piece of Gorilla Glass. Images: Mercedes-Benz AG

Mercedes-Benz is premiering its new MBUX (Mercedes-Benz User Experience) multimedia interface, which will debut in the upcoming EQS battery electric sedan. Dubbed MBUX Hyperscreen, the digital experience promises to transform how we interact with the vehicle, and provide a “wow” effect according to Mercedes-Benz.

The marketing video (below), was almost like one which you might expect from Apple or Samsung, with the carmaker spruiking the technical specs of the computing power behind the new in car system. With 8 CPU cores, 24-gigabytes (GB) of RAM and 46.4 GB per second RAM memory bandwidth, Mercedes-Benz is promising a next-generation infotainment system that delivers an intuitive experience, and actually learns driver behavior.

According to Gorden Wagener, Chief Design Officer Daimler Group, “We merge technology with design in a fascinating way that offers the customer unprecedented ease of use. We love simplicity, we have reached a new level of MBUX.”

Sajjad Khan, Member of the Board of Management of Mercedes-Benz AG and CTO states that the MBUX Hyperscreen continually gets to know the customer better through machine learning, and delivers a personalised infotainment and operating offering before the driver has to even access or scroll through menus.

With context sensitive awareness, the MBUX system proactively displays the right functions at the right time for the user, supported by artificial intelligence. The system is optimised by changes in the surroundings and user behaviour. The so-called zero-layer provides the user at the top level of the MBUX information architecture with dynamic, aggregated content from the entire MBUX system and related services; deep menu layers — a criticism of complex current generation infotainment systems — are a thing of the past.

Mercedes-Benz provides these four examples as use cases:

The user can accept or reject the respective suggestion with just one click:

If you always call a certain friend on the way home on Tuesday evenings, you will be asked to make a corresponding call on that day of the week and at this time of day. A business card with its contact information appears, and - if stored - its image appears. All MBUX suggestions are linked to the user's profile. If someone else drives the EQS on a Tuesday night, this recommendation is not made – or there is another, depending on the preferences of the other user.

If the EQS driver regularly uses the massage function according to the hot stone principle in winter, the system learns and automatically suggests the comfort function in wintry temperatures.

If the user regularly switches on the heating of the steering wheel and other surfaces for seat heating, for example, this is suggested to him as soon as he presses the seat heating.

The chassis of the EQS can be lifted to provide more ground clearance. A useful function for steep garage entrances or sleep policemen. MBUX remembers the GPS position at which the user made use of the "Vehicle Lift-Up" function. If the vehicle approaches the GPS position again, MBUX independently proposes to lift the EQS.

In terms of design, Mercedes-Benz has integrated ambient lighting behind the glass, making the display unit appear to float on the seamless instrument panel. There is also a separate passenger display, a-la Porsche Taycan. If no passenger is seated, the display becomes an animated decorative pattern of stars, so as not to distract the driver with additional infotainment content.

Central and passenger displays utilise OLED technology, where non-active pixels remain switched off, meaning that they appear as deep black rather than a greyish black that is visible on many computer monitors. With a multifunction camera and light sensor to adjust the brightness of the display and pre-empt driver actions, it’s expected that the EQS’ active and passive safety systems will work seamlessly with the MBUX Hyperscreen.

It appears the MBUX Hyperscreen takes the best of the 2021 Mercedes-Benz S-Class infotainment system, and builds upon it, seamlessly integrating multiple displays into a single panel. It’s a distinctly different approach from other EV manufacturers such as Telsa, who prefer to combine all features into a single, centrally-mounted touchscreen. Mercedes-Benz spends billions on R&D and probably millions determining customer preferences, so it’s likely their customers still prefer something akin to a traditional instrument cluster.

While the Mercedes-Benz system provides haptic touch feedback, There’s much criticism about the trend to remove all buttons from a vehicle’s interior. While we think it’s great to seamlessly integrate all system functions into one unit, presumably minimising cost and improving reliability, if that comes at a cost — the ease of quickly operating essential controls — then its not worth it. We hope Mercedes’ “zero-layer technology” and voice control systems can make basic actions like adjusting the climate control temperature or re-routing a navigation destination quick and painless, but we’ll have to wait until the vehicle’s reveal for more information. Mercedes-Benz will reveal the EQA SUV on January 20, and we think the EQS should break cover sometime in the first quarter of 2021.

Mercedes-Benz Accelerates EV Rollout; 8 BEVs In Production by 2022

Mercedes-Benz has today announced announced its ambition to fully electrify the entire product portfolio by 2039 as part of a plan to achieve CO₂ neutrality, and this includes the rollout of eight all-electric Mercedes-EQ models from 2022 built on dedicated electric architecture. The first mass-market Battery Electric Vehicle (BEV) from Stuttgart, the Mercedes-Benz EQC has been available around the world since 2019, and is based on the pre-existing GLC SUV platform.

Images: Mercedes-Benz AU

Update: Mercedes-Benz has released an additional rendering, which you can find below. This vehicle looks to be pretty close to final production design, and will be Mercedes’ first D-segment vehicle without a traditional grille.

Mercedes-Benz has today announced announced its ambition to fully electrify the entire product portfolio by 2039 as part of a plan to achieve CO₂ neutrality, and this includes the rollout of eight all-electric Mercedes-EQ models from 2022 built on dedicated electric architecture. The first mass-market Battery Electric Vehicle (BEV) from Stuttgart, the Mercedes-Benz EQC has been available around the world since 2019, and is based on the pre-existing GLC SUV platform.

The Mercedes-Benz EQS, as shown above and below will be the first to commence production in early 2021, and is essentially the luxurious S-Class reimagined for a zero emissions future. From the camouflagued vehicle, we can see an imposing physical presence -something the S-Class has always been known for- and a low, wide nose, possibly with a faux grille a-la Jaguar i-Pace or an indentation around the badge. The bonnet (hood for you North Americans!) rises steeply into a huge windscreen, which appears to continue above the driver’s head, as is the trend nowadays.

The high bootline and almost fastback look is unusual for the S-Class segment, however the large tail lights with some presumably funky graphics and lightbar spanning the width of the rear should provide a visual family reference to the EQC, while defining the EQS’ unique character.

The side profile looks a little slab-sided under camouflague, with the C-pillar, doors and rear fender covering a large area relative to the glasshouse, however it looks like there may be some interesting surfacing hiding under that blue wrap. The Goodyears on the test car look to be hugging at least 21-inch or 22-inch wheels, as is the trend these days. That’s aesthetics over efficiency for you.

The EQS will be produced in Sindelfingen from early 2021, while the less expensive EQA and EQB models will be produced at the Rastatt and Kecskemét (Hungary) plants respectively. We can expect the world premiere of the EQA on January 20, 2021 according to Mercedes-Benz.

Fast forward to the second half of 2021, and Mercedes-Benz states that the EQE ‘business sedan’ will begin production at the Bremen plant, as well as in Beijing for the Chinese domestic market only. Continuing the the Germans’ fondness for manufacturing SUVs in the United States, the EQE and EQS SUV variants will be manufactured at the brand’s Tuscaloosa Alabama plant.

According to Mercedes, a total of eight Mercedes-EQ electric vehicles will be produced at seven locations on three continents by 2022.

Daimler’s Battery Plans

Battery development, manufacture and supply will obviously be a critical part of this increase in BEVs, and Mercedes-Benz plans to increase investment in the energy side of manufacturing, alongside battery specialists.

Mercedes-Benz and BAIC have jointly set up a battery production plant at the existing location in the Yizhuang Industrial Park in Beijing (China) for vehicles sold in the domestic market.

In addition to two battery plants in Kamenz (Germany) already producing battery systems for Mercedes-Benz, the company plans a future battery plant at the Sindelfingen site, increasing capacity already available from the nearby Untertürkheim plants in preparation for locally built electric models.

Furthermore, Mercedes-Benz is upgrading the Jawor (Poland) battery plant, currently manufacturing battery packs for plug-in hybrid variants of the C,E and S-Classes, to include battery systems for upcoming EQ models, as well as planning a battery plant in the vicinity of the Tuscaloosa Alabama factory.

You can read the full press release below, alongside an interview with Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, Production and Supply Chain.

Mercedes-Benz Sindelfingen plant (Germany): Launch of electric luxury sedan EQS in Factory 56 in first half of 2021

Mercedes-Benz Rastatt plant (Germany): Production of first all-electric compact SUV EQA started - also at Beijing plant (China) in 2021

Mercedes-Benz plant in Kecskemét (Hungary): Decision to locate second all-electric compact SUV EQB. Production launch in 2021 - also at Beijing plant (China)

Mercedes-Benz Bremen plant: Production launch of electric EQE business sedan in 2021 - at Beijing plant soon thereafter (China)

Mercedes-Benz Tuscaloosa plant (USA): SUV variants EQS und EQE begin in 2022

Mercedes-Benz battery production network: Production start of battery systems for EQS and EQE in Untertürkheim/Hedelfingen (Germany) imminent. Production of compact SUV battery systems in Kamenz (Germany), Jawor (Poland) and Beijing (China) plants. Tuscaloosa battery plant will produce batteries for SUV variants of EQS and EQE beginning 2022

15 December 2020, Stuttgart. Mercedes-Benz is targeting leadership in electric drives and vehicle software. The consistent electrification of the entire product portfolio is a key element of the strategic focus "Ambition 2039" and a prerequisite on the way to CO₂ neutrality. In 2022 the portfolio includes eight all-electric Mercedes-EQ models. The global Mercedes-Benz production network is ready for the company’s electric product offensive and is integrating its Mercedes-EQ models into series production in its existing plants.

Markus Schäfer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG; responsible for Daimler Group Research and COO Mercedes-Benz Cars: “With its ‘Electric First’ strategy, Mercedes-Benz is consistently on the path to CO₂ neutrality and is investing heavily in transformation. Our vehicle portfolio becomes electric and thus also our global production network with vehicle and battery factories. We intend to lead in the field of e-mobility and focus in particular on battery technology. We are taking a comprehensive approach, ranging from research and development to production, and also including strategic cooperation.”

The EQS, the first electric luxury sedan from Mercedes-Benz, will start in the first half of 2021 in Factory 56 at the Sindelfingen site (Germany). With the production launch of the electric compact SUV EQA at the Rastatt plant (Germany) and the current decision to locate EQB production in the Hungarian plant in Kecskemét, the company is taking further important steps toward making its product portfolio CO₂ neutral. The course has also been set toward “Electric First” in the global powertrain production network as well. High-efficiency battery systems will also be manufactured and assembled within the production network.

Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, Production and Supply Chain: “The Mercedes-Benz production network is global, digital and flexible, and ready for the upcoming electric offensive – thanks, of course, to our highly qualified and motivated employees worldwide. We are now beginning a real Mercedes-EQ fireworks display. Six electric product launches by 2022 underscore the strength and competence of our Mercedes-Benz production sites worldwide. The production network will have a total of six Mercedes-EQ car locations. Local production of highly efficient battery systems plays a central role in the Mercedes-Benz strategy - coupled with a comprehensive sustainability concept that spans the entire life cycle of the battery all the way to recycling.”

Mercedes-Benz vehicle plants consistently implement electric offensive

In May 2019 production of the EQC (combined power consumption: 21.5 kWh/100 km; combined CO₂ emissions: 0 g/km) at the Mercedes-Benz plant in Bremen (Germany) was integrated into ongoing series production. Just a few months later the German-Chinese production joint venture, Beijing Benz Automotive Co. Ltd. (BBAC), launched EQC production for the local market in China. In 2020 production of the EQV premium electric MPV (combined power consumption: 26.4 kWh/100 km; combined CO₂ emissions: 0 g/km)1 started in Vitoria, northern Spain.

Compact car class customers can look forward to two fully electric compact SUVs in the EQA and EQB in 2021. EQA will celebrate its world premiere on January, 20 2021 as the first fully electric derivative of this compact car. The EQA production launch at the Mercedes-Benz Rastatt plant went smoothly. As with the EQC from Bremen and Beijing and the EQV from Vitoria, which are already on the market, the fully electric models at the Rastatt plant run on the same production line as compact vehicles with conventional and hybrid drives. That means all five vehicles produced in Rastatt are electrified: In addition to the fully electric EQA, the AClass, A-Class sedan, B-Class and the compact SUV GLA are also produced at the Mercedes-Benz plant in Rastatt - with classic combustion engines as well as plug-in hybrid drive. With that the Mercedes-Benz Rastatt plant is making an important contribution on the road to a CO₂ neutral vehicle fleet and to the Mercedes-Benz AG electric offensive. EQA production will also follow next year (2021) at BBAC in Beijing for the Chinese market.

EQB production will launch in 2021 at two locations in the global Mercedes-Benz Cars production network: in the Hungarian Mercedes-Benz plant in Kecskemét for the world market and in the German-Chinese joint venture BBAC in Beijing for the local market. Plant preparation, including employee training and renovation work, is already underway. The compact SUV EQB will be the first purely electrically powered production vehicle from Hungary and will complement the plug-in hybrid portfolio consisting of the CLA and CLA Shooting Brake. The A-Class will also be produced in Kecskemét with a plug-in hybrid drive, in addition to production in the German Mercedes-Benz plant in Rastatt.

Furthermore, in the first half of 2021 production of the EQS electric luxury sedan will begin in Factory 56 at the Mercedes-Benz plant in Sindelfingen (Germany). EQS is the independent, fully electric member in the new S-Class program and is the first to use the new electric architecture for luxury and upper-class electric vehicles at Mercedes-Benz. In Factory 56 the S-Class and, in the future, the Mercedes-Maybach S-Class, and the EQS will be produced in a fully flexible manner on the same line. Factory 56 embodies the future of production at Mercedes-Benz and sets new standards for automobile construction. In Factory 56 efficiency gains of around 25 percent are achieved compared to the previous S-Class assembly. This is made possible by optimizing the entire value chain and full digitalization with MO360, the digital Mercedes-Benz production ecosystem. For further information on this: https://media.daimler.com/marsMediaSite/ko/en/47014243

Furthermore, the Mercedes-Benz plant in Bremen will begin production of the EQE business sedan in the second half of 2021, followed shortly thereafter at the Beijing plant. The EQE thus complements the allelectric portfolio of the two plants. The Beijing plant will then produce a total of four Mercedes-EQ models for the local market.

The Mercedes-Benz plant in Tuscaloosa (USA) is also preparing for production of the EQE SUV and EQS SUV in 2022, which will be produced in the future on the same line with SUVs with conventional and plug-in hybrid drives.

In 2022 a total of eight Mercedes-EQ electric vehicles will be produced at seven locations on three continents. This is possible because the company made early investments worldwide in flexibility and technical equipment with future-oriented Industry 4.0 solutions. In the Mercedes-Benz AG plants, vehicles with different drive types can be produced in parallel thanks to highly flexible structures. With a view to the strategic goal of generating more than half of sales with so-called xEVs, i.e. plug-in hybrids and electric vehicles, from 2030 on and gradually increasing the purely electric share, the high degree of flexibility is a decisive advantage. It enables production to be adjusted at short notice depending on market demand.

smart rounds off the electric Mercedes-Benz Cars portfolio with three additional models. The smart EQ fortwo (combined power consumption: 16.5 kWh/100 km, combined CO₂ emissions: 0 g/km)1 and smart EQ fortwo Cabrio (combined power consumption: 16.8 kWh/100 km, CO₂ emissions combined: 0 g/km)1 are produced in Hambach, France, and the smart EQ forfour (combined power consumption: 17.3 kWh/100 km; combined CO₂ emissions: 0 g/km)1 in Novo Mesto, Slovenia. The next generation of smart electric vehicles will be produced by the joint venture smart Automobile Co., Ltd. in China. This is a joint venture of MercedesBenz AG and the Zhejiang Geely Group (Geely Holding).

Plug-in hybrid drive is important as a key technology and intermediate step toward a purely electric product portfolio. More than 20 plug-in hybrid model variants are already an integral part of the Mercedes-Benz product portfolio. The portfolio will be expanded to include more than 25 model variants by 2025. Their production therefore also plays an important role in the global production network. Plug-in hybrid vehicles are already rolling off Mercedes-Benz Cars assembly lines in almost all car plants.

Global battery production network: a key success factor in the Mercedes-Benz electric offensive

The batteries for the Mercedes-EQ electric vehicles are supplied by a global battery production network with plants on three continents. Local battery production is a key success factor for the Mercedes-Benz electric offensive.

Two plants in Kamenz (Germany), have been producing battery systems for hybrids, plug-in hybrids and electric vehicles since 2012. The second battery factory at the site began operations in 2018 and has been producing the EQC's battery systems since 2019. It was designed from the start as a CO₂ neutral plant and combines, among other things, solar energy, geothermal energy and a combined heat and power plant. The battery systems for the EQA have also recently rolled off the production line at the site. Since the start of production at Accumotive, more than a million batteries based on lithium-ion technology for electric, plug-in hybrid vehicles and 48-volt systems have been produced at the Kamenz site.

Mercedes-Benz and BAIC have jointly set up local battery production at the existing location in the Yizhuang Industrial Park in Beijing (China). This supplies the nearby vehicle plant, which has also added all-electric Mercedes-EQ models to its portfolio with the EQC. Production of battery systems for the EQC started there in 2019. With the start of production of the EQA, EQB and EQE, the plant will manufacture battery systems for a total of four Mercedes-Benz EQ models beginning in 2021.

This year the battery plant in Jawor (Poland) started producing plug-in hybrid batteries for the C, E and SClasses. In the coming year the location will expand its portfolio to include battery systems for the compact Mercedes-EQ models, the EQA and the EQB. Much like the battery plant in Kamenz, the plant was designed from the outset for CO₂ neutral production.

In the future at the Untertürkheim (Germany) site two plants will produce battery systems. Final preparations for the production of the battery systems for the EQS, which will roll off the production line in nearby Sindelfingen in the first half of 2021, are currently underway at the Hedelfingen plant. The battery system for the EQE will also be produced in Hedelfingen. Another battery plant is currently being built in the Brühl facility, which will manufacture battery systems for Mercedes-Benz plug-in hybrids starting 2022. The work on the building has already been completed. The battery plant in Brühl will be fitted with the corresponding equipment in the coming months.

Production of the EQS and EQE SUV models will start in 2022 at the Mercedes-Benz plant in Tuscaloosa (USA). A battery plant is currently being built in the immediate vicinity and will supply highly efficient battery systems for both models. Work on the building has already been completed. The ultra-modern systems will be installed in the coming months.

In addition, the Mercedes-Benz production strategy currently provides for another battery plant at the Sindelfingen site.

Together with local partner Thonburi Automotive Assembly Plant (TAAP), Mercedes-Benz Cars set up a battery production facility in Bangkok (Thailand) and began operations in 2019. Battery systems for the current C, E and S-Class plug-in hybrids are manufactured at the site. Preparations are also being made there to manufacture drive batteries for all-electric Mercedes-EQ brand vehicles.

Electric First und Ambition2039: CO₂ neutral mobility und production

Under “Electric First,” Mercedes-Benz is pursuing the consistent electrification of all model variants and vehicle types as a clear objective. The decisive factor here over the next few years is the gradual increase in the purely electric share of the vehicle portfolio. So-called xEVs, plug-in hybrids and fully electric vehicles, should account for more than half of sales by 2030 - and the trend is rising. Electrically powered vehicles from Mercedes-Benz are enjoying increasing popularity. The company delivered a total of 45,000 electric vehicles and plug-in hybrids (xEVs) worldwide in the third quarter of 2020.

With “Ambition2039,” Mercedes-Benz introduced its path to CO₂ neutrality over a year ago. Vehicle production plays a crucial role in this regard. As early as 2022 the company’s Mercedes-Benz car and van plants will produce CO₂ neutrally around the world. This includes more than 30 car and van plants, as well as battery plants.

Brief interview

“We’re producing the Mercedes-EQ models the Mercedes way: Completely digital and flexible, highly efficient and maximally sustainable.”

Questions for Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, Production and

Supply Chain

Mr. Burzer, are you equipped for the production of electric vehicles in your production network?

The Mercedes-EQ production network is ready for our electric offensive. We started this transformation several years ago and set up our plants with maximum flexibility. The Mercedes-EQ electric models are gradually being integrated into our existing vehicle plants worldwide. They come off the same lines as vehicles with combustion engines or plug-in hybrid drives. The same applies to all of our Mercedes-Benz car plants - a total of six on three continents. This concept is particularly advantageous because demand for electric and electrified vehicles is developing very differently by region and we can adjust our production planning accordingly on short notice. In this way we can manufacture exactly what our customers want.

What specifically does your production planning for the upcoming model offensive look like?

One thing is certain: the proportion of all-electric vehicles in our portfolio will increase sharply in the coming years. By 2030 more than fifty percent of our vehicles will roll off the assembly line as so-called xEVs. Plug-in hybrids and hybrids will therefore continue to play an important role in our production planning over the next few years. However, our target is clearly designed for 100 percent Mercedes-EQ and we are directing our capacity precisely in this direction. We are preparing our production, as well as our employees, step by step for this change. Our sustainability concept is also a central focus: from 2022 on we will produce CO₂ neutral in our Mercedes-Benz plants worldwide.

What, specifically, were the challenges?

Every vehicle launch during ongoing production comes with challenges. That, of course, also applies to electric vehicles. However, thanks to the know-how in our plants and cross-location system planning, we could quickly develop and implement flexible solutions. The consistent digitalization of our processes through our digital production ecosystem MO360 also made a significant contribution. An important factor here, of course, is attaining targeted qualifications for our colleagues in our plants, which we consistently promote.

How will powertrain production continue in the future?

For the global Mercedes-Benz powertrain production network, the shift toward e-mobility poses a special challenge. However, we are determined to continue aligning our drive division to this change and make it sustainable for the future. We have already built up extensive know-how in our powertrain plants in recent years. It starts with the expansion of our battery production network and includes, among other things, manufacturing and assembling parts of the electric drivetrain ourselves. Still, it’s also clear that the drivetrains of the future will differ significantly from those of today.

You will manufacture the batteries for the Mercedes-EQ models in house?

The local production of batteries is an essential success factor in our electric offensive. With a view to steadily increasing demand and, in accordance with our production planning, we are setting up our global battery production network to be flexible worldwide. Today we already produce batteries in Kamenz, Bangkok and Beijing. The ramp-up of our battery plants in Hedelfingen and Jawor is imminent and our colleagues in Brühl and Tuscaloosa are already preparing to start production in 2022. Our production network is very well positioned for the Mercedes-EQ model offensive.

Which new electric model are you personally most looking forward to?

Basically, I look forward to every new Mercedes-Benz. A very special milestone is certainly the upcoming EQS production launch. It will roll off the assembly line, together with the S-Class, in our new Factory 56 at the Mercedes-Benz plant in Sindelfingen. Here we’re setting the course for our entire production network: With the most modern production technologies Factory 56 is a blueprint for our global network. At the same time, it bolsters our claim - the Mercedes way - to the production of the Mercedes-EQ models: completely digital and flexible, highly efficient and maximally sustainable.