Mercedes-Benz reveals EQS EV interior before worldwide debut on April 15th

Mercedes-Benz has shown us the production ready interior of its upcoming EQS sedan, and its a thing of illuminated beauty if timber, glass and OLEDs are your thing. The EQS is the flagship vehicle for Mercedes-Benz’ EQ brand—literally the S-Class of the electric world—so you can expect that the designers have gone all out.

Mercedes-Benz has shown us the production ready interior of its upcoming EQS sedan, and its a thing of illuminated beauty if timber, glass and OLEDs are your thing. The EQS is the flagship vehicle for Mercedes-Benz’ EQ brand—literally the S-Class of the electric world—so you can expect that the designers have gone all out.

The MBUX Hyperscreen is the (optional) pièce de résistance, combining all features of the drivers’ instrument panel, dashboard and infotainment into a single glass panel. Mercedes-Benz likes to reference historical details, and the thin silver shadow frame around the screen, combined with the single ventilation band and a narrow leather frame are reminiscent of classic instrument panels according to the automaker.

If one doesn’t option the Hyperscreen, the interior looks quite similar to the latest W223 S-Class. with a single, vertically mounted touchscreen. The EQS is set to debut on April 15, before going on sale in July/August 2021. Scroll down for 10 interesting facts about the interior of the EQS:

The EQS interior with hyperscreen and floating centre console.

10 interesting facts about the interior of the EQS:

With the MBUX Hyperscreen, multiple displays merge seamlessly to create an impressive curved screen band over 141 centimetres wide. The area perceived by the occupants measures 2432.11 sq. cm.

The large glass covering the MBUX Hyperscreen is curved in three dimensions in a moulding process at temperatures of approx. 650°C.

The HEPA filter (High Efficiency Particulate Air) as part of the optional equipment ENERGIZING AIR CONTROL Plus cleans the incoming outside air at its very high filtration level. Over 99.65 percent of particles of all sizes are eliminated, and the adsorption area is equivalent to about 150 football fields.

The key applications are always offered on the top level in the field of vision, depending on the situation and context, as part of Mercedes’ “zero-layer design”.

The "Mercedes-Benz pattern" is used in several places in the EQS interior such as on the backlit trim elements or on the passenger display as a digital decorative image. It is an abstracted, three-dimensional star pattern based on an early trademark of the Daimler Motorengesellschaft.

The EQS comes with the two soundscapes Silver Waves and Vivid Flux, and they can be selected or switched off as sound experiences on the central display. The algorithms and sounds for the sound design are created in-house at Mercedes-EQ by physicists, sound designers, media designers and mechatronics specialists.

Mercedes-Benz is showcasing its modern, leather-free material for the interior, NEOTEX. According to the company, it “combines the look of nubuck leather and high-tech neoprene”. There are eight coordinated colour combinations in the interior.

More than 40 new inventions have found their way into EQS. In addition, 20 design applications protect the design of the vehicle.

The design of the door panels borrows from the interior design of modern living spaces. Doors and their centre panels emerge from behind the MBUX Hyperscreen to span the space. A surface-mounted modular body floats like a sideboard in front of the door panel.

ENERGISING COMFORT features three programmes—Forest Glade, Sounds of the Sea and Summer Rain—which provide an immersive and realistic on-board sound experience. These calming sounds were created in consultation with the acoustic ecologist Gordon Hempton.

SEA Electric to purchase 1,000 battery sets from Soundon New Energy Technology Co for electric trucks

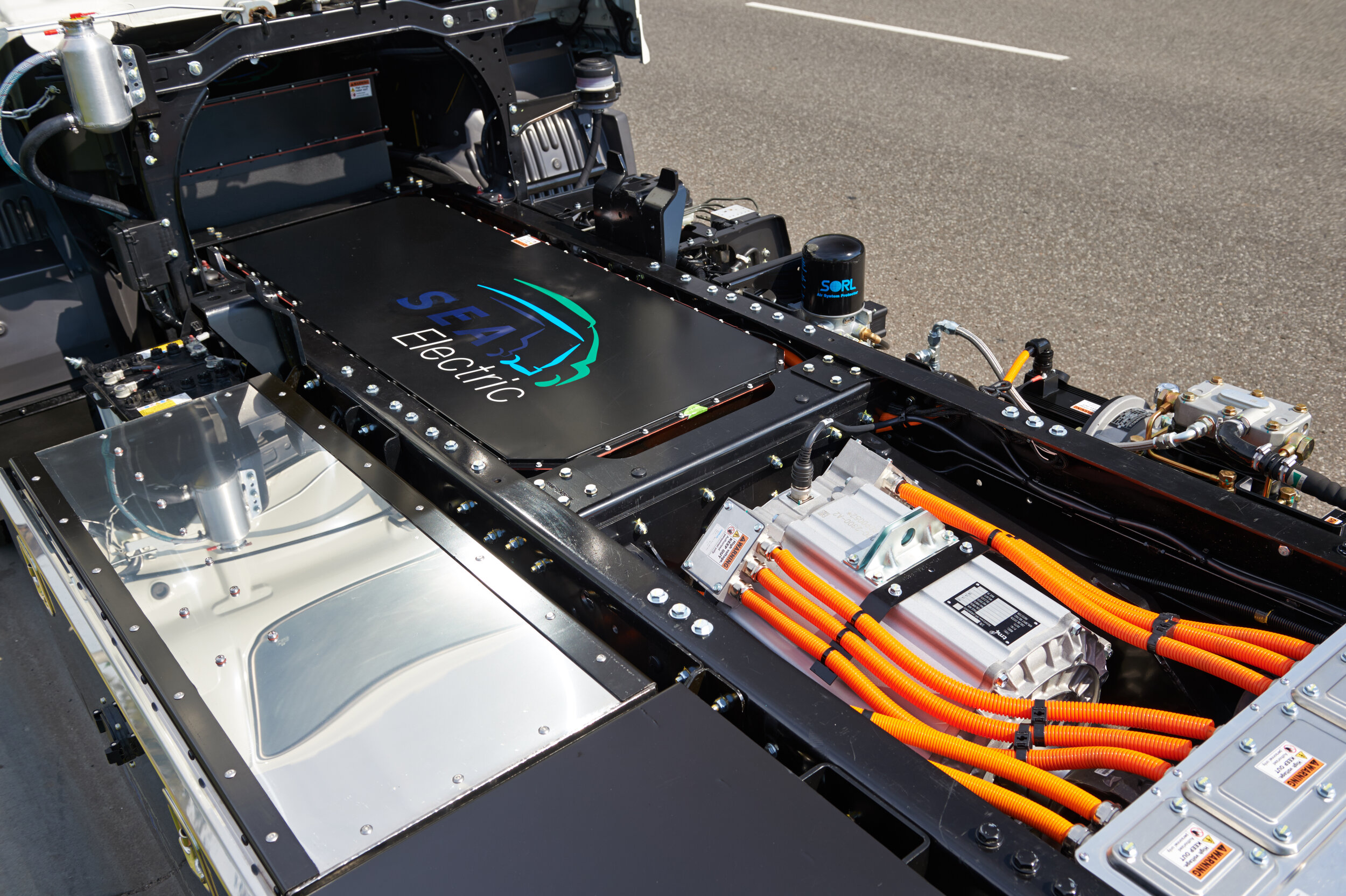

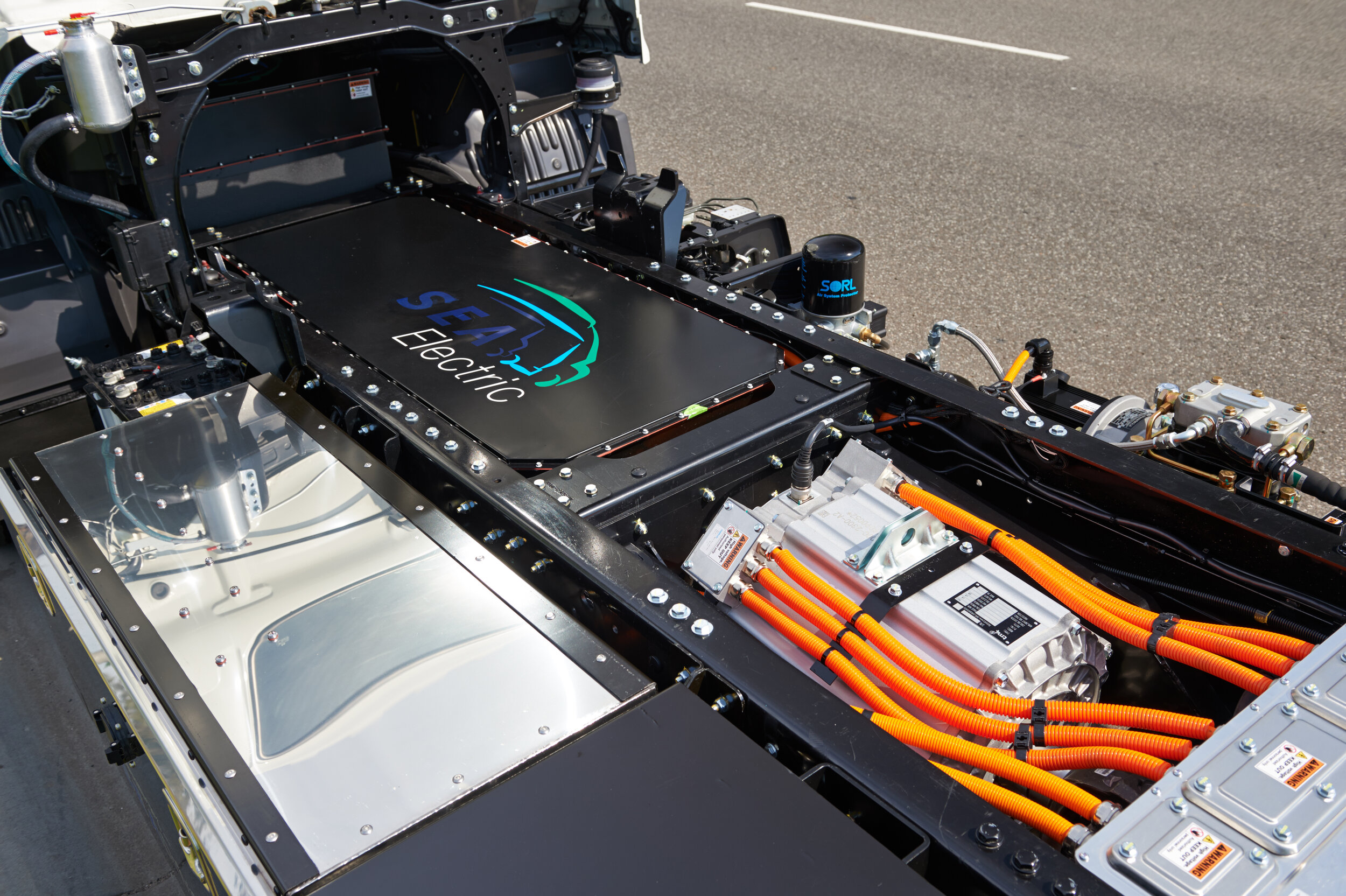

Global automotive technology company SEA Electric has expanded its global reach through the purchase of 1,000 electric vehicle batteries from long-time technology partner Soundon New Energy Technology Co. The newly formed arrangement immediately follows SEA Electric’s recently announced US$42 million in equity financing news.

Global automotive technology company SEA Electric has expanded its global reach through the purchase of 1,000 electric vehicle batteries from long-time technology partner Soundon New Energy Technology Co. The newly formed arrangement immediately follows SEA Electric’s recently announced US$42 million in equity financing.

Soundon has been providing SEA Electric with batteries since 2012, and the two companies have worked together closely on the development of seven SEA-Drive battery solutions over the course of the nine year relationship. SEA Electric is leveraging the cost benefits of Soundon’s battery and power electronics technical expertise, and their production efficiencies. The deal also allows SEA Electric to realise a significant 36 percent reduction in kilowatt hour (kWh) unit cost, and fulfilment of the battery production is expected to be completed in Q2 2021.

Soundon New Energy Technology’s manufacturing centre in China. Image: SEA Ealectric

According to Tony Fairweather, SEA Electric president and founder, Soundon is not only a world-class leader in innovation and battery technology, but highly regarded for its product quality, on time delivery, and competitive pricing. “Our long-term relationship with Soundon has been a very successful commercial journey and we anticipate continuing to share our global successes along the way.” While the majority of the initial 1,000 battery units are slated for the United States, the balance will go to SEA Electric inventories in Australia, New Zealand and Southeast Asia, along with the company’s first entry into the European market.

SEA Electric’s SEA-Drive technology fits hundreds of OEM platforms according to the company, with this large order from Soundon shared cross three major power-system models:

An Isuzu truck with SEA-Drive technology. Image: SEA Electric

SEA-Drive 70 – contains 88 kilowatt hours (kWh)

SEA-Drive 100 – contains 101 kilowatt hours (kWh)

SEA-Drive 120 – contains 138 kilowatt hours (kWh)

Wu Peng, Vice President of Sales and Marketing for Soundon commented that “this is a significant milestone in our partnership with SEA Electric. Receiving this 1,000-unit order not only facilitates SEA Electric’s substantial global growth, it also positions Soundon as a leader in the export market for commercial electric vehicles. It’s a winning proposition for all.”

With global headquarters and key leadership in Los Angeles, SEA Electric currently has operations in five countries and more than one million miles of independent Original Equipment Manufacturer (OEM) testing and in-service operation in all markets.

SEA Electric is an Australian success story, and currently partners with commercial vehicle OEMs, dealers, operators and upfitters to deliver zero-emissions trucks around the world. The company is expected to deliver more than 1,000 electric commercial vehicles this year. The company forecast is to have more than 15,000 vehicles on the road by the end of 2023.

Soundon New Energy Technology’s manufacturing centre in China. Image: SEA Ealectric

An example of SEA Electric’s SEA-Drive unit for OEMs. Image: SEA Electric

Porsche aims for faster charging, higher energy density batteries and own fast charging network

As part of the Volkswagen Group’s inaugural Battery Day presentation, Porsche revealed continuing research and development into high performance battery and charging technologies, including the replacement of graphite with silicone in battery cell anodes.

As part of the Volkswagen Group’s inaugural Battery Day presentation, Porsche revealed continuing research and development into high performance battery and charging technologies, including the replacement of graphite with silicone in battery cell anodes.

Battery Technology

"The battery cell is the combustion chamber of tomorrow," says Oliver Blume, Chairman of the Executive Board of Porsche AG. "Our electrified high-performance sports and racing cars place the highest demands on battery technology. To meet these demands, Porsche needs special high-performance cells. Silicon has big potential."

Porsche’s Performance Battery Plus and 800V architecture as fitted to the Taycan Turbo.

An EV battery is made up of a few core components: the anode, cathode, separator, electrolyte, and one positive and one negative current collectors. Lithium ions are stored across both the cathode and anode, and the electrolyte carries these positively charged ions from the cathode to the anode during charging, and from the anode to the cathode during discharge (driving).

Porsche is looking at new battery cell chemistries to allow efficient operation in extreme temperatures, and to improve reliability and longevity in DC rapid charging. Porsche states that new batteries will begin testing in limited-production road vehicles and within their customer motorsport program. Porsche has also outlined a desire to ensure that there is a “completely European production chain for high-performance batteries”, implying a geopolitical need to avoid any reliance on dominant South Korean and Chinese cell providers LG Chem and CATL.

Battery modules in the Performance Battery Plus.

Porsche’s Own Charging Network

Porsche also announced plans to roll out a DC fast-charging network across important European autobahns, highways and motorways. Clearly looking to imitate Tesla’s Supercharger network—at least on a small scale—which provides industry-leading convenience and ease of use for Tesla owners, Porsche’s charging stations will feature six to twelve charging points, from 350kW and up.

The DC chargers at Porsche’s Leipzig customer centre could be a model for the company’s future highway chargers.

According to Blume, "An important prerequisite for electromobility is fast and convenient charging. That is why we are currently working on the details of a concept for our own fast-charging stations. We will select attractive locations for these in order to offer our customers the most comfortable and fastest long-distance travel experience possible."

Exact locations are not known at this stage, and plans outside Europe seem unlikely, but Porsche plans self-service lounge facilities with smartphone app access for its customers. These Porsche charging stations should complement the Ionity network nicely, and you can bet that the charging sites will feature Porsche’s usual high-end techno-minimalist look and feel. As the brand expands its electric offerings beyond the Taycan to the Macan and potentially the Cayenne by 2025, this rollout should quell future customers’ concerns about range anxiety, at least in Europe.

Porsche Leipzig’s customer centre features 350 kW DC/22 kW AC charging.

Australian commercial EV manufacturer SEA Electric completes US$42 Million equity financing

This week, SEA Electric announced it has closed initial private placement equity financing for total gross proceeds of approximately US$42 million. The net proceeds from the investment will allow SEA Electric to solidify its position as a market leader in the electrification of commercial vehicles whilst funding its considerable backlog and facilitating more pilot programs with operators.

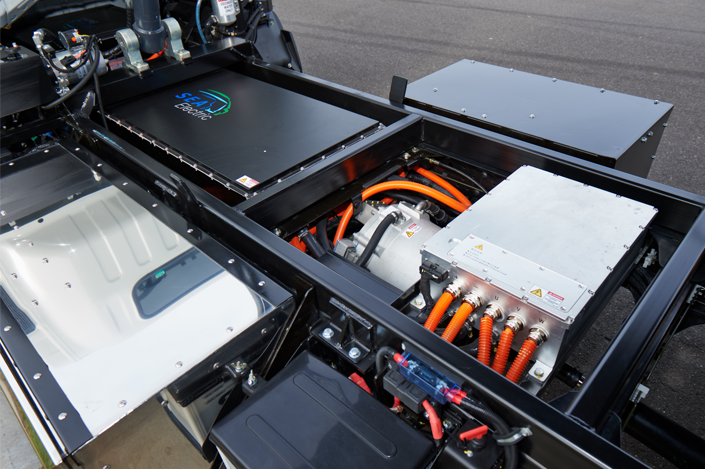

The SEA-Drive Power System. Images: SEA Electric

Founded in Australia in 2012, SEA Electric Holdings Pty Ltd. (SEA Electric) has become an international success story with its proprietary electric power-system technology (known as SEA-Drive®) now found across the world's urban delivery and distribution fleets.

With products in seven countries including USA, Canada, Australia, New Zealand, Thailand, Indonesia and South Africa, SEA Electric has more than one million miles of independently OEM-tested and in-service operation behind its technology.

This week, SEA Electric announced it has closed initial private placement equity financing for total gross proceeds of approximately US$42 million. The net proceeds from the investment will allow SEA Electric to solidify its position as a market leader in the electrification of commercial vehicles whilst funding its considerable backlog and facilitating more pilot programs with operators.

According to President and Founder Tony Fairweather, the financing allows SEA Electric to accelerate its global sales efforts and further utilize its proprietary Sea-Drive® 120b battery power system, while strengthening the delivery and distribution transportation segment for vehicles that operate in urban and metropolitan areas.

SEA Electric issued approximately 1.1 million Series A Preferred Shares at a price of US $40.1995 per share, convertible into common shares of SEA Electric at the option of subscribers and automatically convert to common shares under certain conditions, including SEA Electric completing a public transaction.

Fairweather stated, “We are very pleased to have completed a heavily oversubscribed equity financing and are excited to welcome aboard a global set of institutional investors as partners. The financing allows SEA Electric to grow our backlog as we explore options to seek a public listing in the United States this year.”

SEA Electric currently partners with commercial vehicle OEMs, dealers, operators and upfitters to deliver a new range of zero-emissions trucks and is on schedule to deliver more than 1,000 electric commercial vehicles this year. The company forecast is to have more than 15,000 vehicles on the road by the end of 2023.

“2021 will see a paradigm shift in the way developed markets facilitate uptake of commercial electric vehicles and the unstoppable momentum will build year-after-year” said Fairweather.

It is a notable achievement that in the face of lacklustre government support for clean technology in Australia, a company like SEA Electric has successfully conquered the international market in eight years. Companies like SEA Electric, Tritium and Evans Electric exemplify the technical and creative capital that exist in Australia that must be nurtured to support jobs, manufacturing and the transition to clean energy technologies.

Volkswagen's 2020 "Project Trinity" promises step change in EV range and charging

Volkswagen has announced that they are working on a cutting-edge electric saloon to be built in Wolfsburg from 2026. Expected to be similar in size to the company’s Arteon fastback saloon, Volkswagen promises ”new standards in terms of range, charging speed and digitization—as well as being able to drive highly automated according to Level 4.”

Volkswagen has announced that they are working on a cutting-edge electric saloon to be built in Wolfsburg from 2026. Expected to be similar in size to the company’s Arteon fastback saloon, Volkswagen promises ”new standards in terms of range, charging speed and digitization—as well as being able to drive highly automated according to Level 4.”

Based on the company’s MEB electric vehicle architecture, the Project Trinity EV should feature advanced vehicle autonomy and connectivity systems.

According to Volkswagen, the project name Trinity is derived from the Latin “trinitas” and stands for the tri-unity. Accordingly, Trinity stands for three crucial themes: a newly developed electronics platform with state-of-the-art software, the simplification of the supply structure, and fully networked and intelligent production at the main plant in Wolfsburg.

Volkswagen claims the newly developed vehicle architecture will set standards in terms of range, digitalization and charging speed, with the aim of Project Trinity to allow customers to charge as fast as traditional refueling.

By the planned start of series production in 2026, it is anticipated that Trinity will reach Level 2+ and be technically ready for Level 4.

“We are using our economies of scale to make autonomous driving available to many people and to build a learning neural network. In this way, we are creating the conditions for the continuous exchange of data from our vehicle fleet—for example, on the traffic situation, on obstacles or on accidents,” says Ralf Brandstätter. Trinity thus gives people time and saves them stress. After a long highway trip, you arrive at your destination relaxed. Because you have been driven by a chauffeur to your vacation or to your home after work. “Trinity therefore becomes a kind of 'time machine' for our customers,” says Ralf Brandstätter.

With the production of the series version, the Wolfsburg plant will become a showcase for state-of-the-art, intelligent and fully networked production processes. “We will completely rethink the way we build cars and introduce revolutionary approaches. Digitalization, automation and lightweight construction play an important role here,” says Ralf Brandstätter.

Future vehicle models such as Trinity will be produced with considerably fewer variants, and the hardware will be largely standardized. The cars will then have virtually everything on board and customers will be able to activate desired functions “on demand” at any time via the digital ecosystem in the car. This will significantly reduce complexity in production.

By developing the automobile into a software-based product, Volkswagen is creating the conditions for new, data-based business models. Entry barriers to individual mobility are to be lowered, while at the same time offering even more attractive usage packages. Volkswagen intends to generate additional revenue in the usage phase—for charging and energy services, for software-based functions that customers can book as needed, or for automated driving. “In the future, the individual configuration of the vehicle will no longer be determined by the hardware at the time of purchase. Instead, customers will be able to add functions on demand at any time via the digital ecosystem in the car,” says Ralf Brandstätter.

According to Inside EVs, Volkswagen clarified some issues with what Ralf Brandstätter told Welt Am Sonntag in an interview about Trinity. The Volkswagen brand’s CEO stated to the German newspaper the Trinity would be around 4 meters (158 inches) long and cost about €35,000.

Volkswagen told InsideEVs there was a mistake in the quote. It should be “more than 4 meters.” According to the company, the car will be similar in size to the ID.4, with a length between 4.5 m (177 in) and 4.7 m (185 in).

Energy Renaissance announces start of construction for Australia's first lithium-ion battery factory

Australia will soon be producing lithium-ion batteries onshore, thanks to start-up Energy Renaissance. With funding raised exclusively from private investors, Energy Renaissance has committed to manufacturing batteries at a site in Tomago, NSW, only a few kilometres from the Port of Newcastle.

Australia will soon be producing lithium-ion batteries onshore, thanks to start-up Energy Renaissance. With funding raised exclusively from private investors, Energy Renaissance has committed to manufacturing batteries at a site in Tomago, NSW, only a few kilometres from the Port of Newcastle.

Energy Renaissance’s 4,500 sqm purpose-built facility will manufacture Australian made batteries that are, according to the company “safe, secure, affordable and optimised to perform in hot climates.” Energy Renaissance will be manufacturing energy storage systems for the transport industry including busses and light commercial vehicles, as well as batteries for grid-scale, mining industry and community storage uses.

Energy Renaissance will have an initial battery production capacity of 48MWh per year and the capacity to expand to 180MWh per year in 2022. Energy Renaissance’s long-term plans are to develop a 1GWh battery manufacturing facility, and potentially grow to 5.3GWh over the next decade.

Construction of the facility will commence in April 2021 with a small-scale production trial run of batteries to start by July 2021, ramping up to full-scale production in October 2021.

CIS Solutions recently undertook an independent economic impact analysis, and concluded that an Australian advanced manufacturing industry supplying and exporting battery-grade chemicals and materials would create over 100,000 construction and 80,000 operational jobs and add AUD$7.3 trillion in export revenue. (Note that we haven’t been able to find a link to this study online)

There has been a dramatic decline in appetite for Australian iron ore and coal both domestically and internationally, and the Australian Government has been rather slow in realising that lithium—a metal found in abundance in Australia—has the potential to not only generate serious export dollars as global demand for batteries rises over the next decade, but to also shore up skilled manufacturing jobs locally, assisting the transition and retraining of mining sector workers.

Energy Renaissance is perfectly placed to take advantage of this; it’s investment to process raw materials locally in a region already known for mining means that the company should have a captive employment market available, as well as access to global markets via the nearby port.

With the New South Wales committing to purchase over 8,000 electric buses, this should present a great opportunity for Energy Renaissance to find local customers.

The government’s Minister for Industry, Science and Technology Karen Andrews and the Prime Minister, Scott Morrison were also present at Energy Renaissance’s manufacturing facility launch, and were keen to jump in with their own announcement, releasing the Resources Technology and Critical Minerals Processing road map in the Commonwealth Government’s Modern Manufacturing Strategy.

The Strategy has the following goals:

2 years: Improved capability to bring products quickly to market, through improved market development activities and investment made in critical enablers.

5 years: Foster increased collaboration with relevant sectors and international supply chains, increase exports and grow private sector investment.

10 years: Australia seen as a regional hub for resources technology and critical minerals processing, with significant R&D advancements, retention in intellectual capital for SMEs and significant volume and value of exports.

We’ll keep you updated as Energy Renaissance’s facility comes together.

Read more about the government’s strategy here: https://www.industry.gov.au/data-and-publications/resources-technology-and-critical-minerals-processing-national-manufacturing-priority-road-map

Hyundai's Nexo fuel cell electric vehicle forms Australia's first hydrogen fleet

Hyundai has become the first manufacturer to supply a hydrogen fleet in Australia, to the government of the Australian Capital Territory (ACT). 20 zero-emission Hyundai NEXO fuel cell electric vehicles have been registered and are set to hit the road in March as part of the ACT government fleet.

Hyundai has become the first manufacturer to supply a hydrogen fleet in Australia, to the government of the Australian Capital Territory (ACT). 20 zero-emission Hyundai NEXO fuel cell electric vehicles have been registered and are set to hit the road in March as part of the ACT government fleet.

The NEXO fleet represents the first deployment of fully certified, ADR-approved Fuel Cell Electric Vehicles (FCEVs) in Australia, as well as the first use of hydrogen vehicles by a Government in Australia.

ACT Government welcomes the new vehicles

ACT Minister for Climate Change and Sustainability, Shane Rattenbury MLA, said that the NEXO fleet deployment is a positive step towards mitigating climate change. "Tackling climate change means tackling transport pollution, and zero-emission vehicle technology is a key part of this,” Mr Rattenbury said.

Australia’s first publicly available hydrogen station is scheduled to open in Canberra later this month (March 2021) and will provide the capability for 700-bar rapid refueling of the NEXO fleet.

EV Brief understands that hydrogen will be electrolysed on site (or close to), and will be powered by renewable energy from a Neoen wind farm just outside Canberra.

The initial 20 ACT government NEXO vehicles will be followed by a fleet of five of the FCEVs for the Queensland government, which are presently inbound to Australia.

The NEXO was released in 2018, but still looks contemporary. NEXO has a range of 666km (WLTP), with a refueling time of three to five minutes, and emits only water vapour from its exhaust. Hyundai claims the NEXO “purifies the air as it drives”, and that for every hour that the NEXO is on the road, 26.9 kilos of air is purified.

Hyundai’s NEXO emits only water from its tailpipes.

The heavy duty filtration system of the NEXO removes 99.9% of PM2.5 fine particulate matter from polluted air according to Hyundai.

“The deployment of 20 NEXO fuel cell electric vehicles for the ACT government is a significant milestone in Hyundai’s long-term commitment to hydrogen as a key to zero-emissions transport solutions for Australia,” Hyundai Motor Company Australia Chief Executive Officer, Jun Heo said. “As part of a line-up that includes the hybrid and plug-in hybrid IONIQ, and the pure electric IONIQ and Kona models, NEXO also underscores Hyundai’s leadership in eco-mobility,” he said.

Our take:

Hydrogen is certainly going to be important in the future, particularly in manufacturing and heavy industry as a replacement for gas where renewables aren’t practical. Hydrogen even makes sense for commercial vehicles, government fleets and busses where it can be electrolysed on site via renewable energy.

The biggest problem comes from the required energy to electrolyse hydrogen; Only 38% of the original electricity used actually makes it to the driven wheels of a vehicle. By comparison, a battery electric vehicle (BEV) achieves around 80-90% efficiency.

Hydrogen has to be compressed, chilled and transported to a refueling station and then when inside the vehicle, needs to be converted to electricity and finally into powering the motor. Not only do BEVs break the whole refining/transportation/refueling regime that lines the pockets of big oil, they allow consumers to power their own vehicles from 100% renewable energy in the form of solar panels on their home.

Hyundai and Toyota are two of a small number of manufacturers pursuing hydrogen development, but the rest of the industry seems to be heading for a pure electric future.

On the road with Highway Navigation Guided Pilot, the semi-autonomous driving tech from XPeng

XPeng Inc. released their Highway Navigation Guided Pilot (NGP) software to customers via an over-the-air (OTA) update on January 26, and has already logged over one million kilometers within its first 25 days.

XPeng Inc. releases autonomous technology

XPeng Inc. released their Highway Navigation Guided Pilot (NGP) software to customers via an over-the-air (OTA) update on January 26, and has already logged over one million kilometres within its first 25 days.

Youtuber Wheelsboy visited XPeng’s headquarters, and demonstrated the company’s NGP technology on an electric P7 sedan:

XPeng’s NGP features

Owners are required to watch an instructional video and complete a quiz before the software features are unlocked. Once operational, XPeng’s NGP can perform the following functions:

Automatic lane changing and overtaking with lane optimisation

Automatic speed limit adjustment

Automatic changing of highways

Automatic highway ramp entering and exiting

Collision avoidance, in -lane and while changing lanes

Identification and avoidance of obstacles on the road

Customers are required to watch a safety video regarding the operation of NGP before using the features. Image: XPeng

XPeng is working hard to gather data from customers on the road to improve their technology. NGP utilises cameras, sensors, radar and lidar for its suite of autonomous functions, whereas Tesla has avoided lidar technology, with Elon Musk going so far as to say “lidar is a fool’s errand” and “Anyone relying on lidar is doomed. Doomed!”

We know that Tesla’s autonomous systems are a technological tour-de-force, with dual chips for redundancy, and a processor capable of over 144 trillion operations per second (TOPS). For comparison, XPeng’s in-car computer is currently rated at 30 TOPS, but the company promises increases to the computing power over time. We’re yet to see how well XPeng’s NGP software works outside of China, but Wheelsboy’s video demonstrates promising signs of competent driver assistance technology.

NIO Reveals Striking ET7 Sedan with 1,000km Range

NIO has pulled the covers off the new ET7 Sedan at its annual NIO Day. NIO claims exceptional range, performance and luxury from this striking sedan, as well as the introduction of Lidar technology — a first in all-electric consumer vehicles — to aid autonomous operation.

NIO has pulled the covers off the new ET7 Sedan at its annual NIO Day. NIO claims exceptional range, performance and luxury from this striking sedan, as well as the introduction of Lidar technology — a first in all-electric consumer vehicles — to aid autonomous operation.

Exterior Design

Clearly carrying cues from the ET Preview displayed in 2019, the ET7 is objectively a handsome car. The short, squat front end is muscular and sporty, and its small, narrow headlights and grille-less front end are reminiscent of Hyundai’s 2021 Kona. The deliberate, triangular slots for the additional front lights remind us of the Kia Stinger (no bad thing).

Images: NIO

With a large glasshouse profile, NIO designers have kept the side of the vehicle simple yet cohesive. One accentuating crease near the top of the door plays beautifully with light, while a rising ‘power line’ on the lower part of the doors is reminiscent of Audi’s A5 and A7 Sportback models.

The tapering rear roofline and chunky three quarter panel remind us of the Polestar 2, without the squared-off edges. It’s elegant — if a little unexciting — but does well to give the rear presence while masking the bulk of the vehicle.

The rear itself shares design elements the Audi A7 and Tesla Model 3, with what looks to be an integrated retractable spoiler as well as a fixed ducktail lip in the boot (trunk) lid, and plenty of horizontal lines to accentuate dynamism and presence. Plus the (now ubiquitous) LED light bar running the width of the vehicle as seen on vehicles from Polestar to Porsche.

Interior

The interior is a clean combination of Volvo Scandi-minimalism, Tesla austerity and familiar design cues from the NIO family. NIO has made a big deal about "invisible" smart air vents on both front and rear row, frameless windows and soft close doors with flush door handles.

NIO has compared the interior of the ET7 to a second living room, and it appears to be a comfortable space for four adults on a long trip. Standard equipment includes smart air suspension, heating, ventilation and massage functions all round. There is a full length glass roof, a 23 speaker audio system, dual-LCD screen dashboard and NIO’s Nomi; the automotive world’s first in-vehicle digital assistant.

Battery and Drivetrain

The NIO ET7 will initially be offered with two battery options; a 70 kWh with 500km (310 miles) of range, and 100 kWh with 700km (440 miles) range.

NIO plans a version with a solid-state battery packing 150 kWh and a density of 360wh/kg for later in 2022, which the company claims will offer 1,000km (620 miles) of range. While a number of automakers including Toyota have publicly discussed plans to develop solid state batteries and claim many advantages over Tesla’s technology, for now, solid state batteries have inferior cycle life to batteries with liquid electrolytes, such as Tesla’s setup.

NIO has also revealed Power Swap 2.0, it’s battery-as-a-service (BaaS) swap technology. While many — including us to a degree — remain sceptical about the scalability of this battery swap model, many NIO owners and Chinese customers generally are fond of the technology, which allows drivers to either turn up or book in a time to swap their vehicle’s battery pack in a matter of minutes. NIO claims the stations will be able to store 13 battery packs and provide up to 312 battery swaps per day. NIO plans over 500 battery swap stations by the end of 2021. NIO will offer a monthly payment option for this battery swap technology.

The ET7 offers an all wheel drive dual motor setup, with a permanent magnet motor in the front and an induction motor in the rear. It has a peak system output of 480 kW and 850 Nm of torque. NIO quotes a 0 to 100 km/h (62 mph) time of 3.9 seconds.

Autonomy and Vehicle Technology

One hundred million. That’s the number of real-world kilometres driven using Tesla’s Autopilot system, and its the reason Tesla will be so hard to beat when it comes to autonomous driving. During NIO’s presentation of the ET7, the company praised the new NAD (NIO Autonomous Driving) system, with its Lidar, eleven eight-megapixel cameras and crazy powerful — 1,016 Tera Operations Per Second (TOPS) — Nvidia chip, but what they didn’t talk about was software.

Elon Musk has long dismissed Lidar on passenger vehicles as unnecessary, and has even claimed “LiDAR is a fool's errand…anyone relying on LiDAR is doomed.” Tesla has stuck with a system of cameras and radar for the “eyes” of its autopilot system, but Tesla has had vehicles gathering data in the real-world for years now, with its Neural Network processing trillions of data points. In the video by Whole Mars Blog, a Tesla Model 3 successfully navigates from San Francisco to Los Angeles with almost zero human intervention, with just its computing power, and Tesla’s radar and camera system. Seriously impressive.

The NIO ET7 is due for release sometime in 2022, and pricing is as follows:

NIO ET7 (70 kWh)

448,000 yuan (US$69,185)

with BaaS: 378,000 yuan ($58,375) plus 980 yuan ($151) per month

ET7 (100 kWh)

506,000 yuan (US$78,142)

with BaaS: 378,000 yuan ($58,375) plus 1,480 yuan ($229) per monthET7 Premier edition (100 kWh)

526,000 yuan (US$81,230)

with BaaS: 398,000 yuan ($61,463) plus 1,480 yuan ($229) per month

Mercedes-Benz Reveals Unique Hyperscreen for Upcoming EQS EV

Mercedes-Benz is premiering its new MBUX (Mercedes-Benz User Experience) multimedia interface, which will debut in the upcoming EQS battery electric sedan. Dubbed MBUX Hyperscreen, the digital experience promises to transform how we interact with the vehicle, and provide a “wow” effect according to Mercedes-Benz.

The new MBUX Hyperscreen comprises three individual OLED displays underneath a single piece of Gorilla Glass. Images: Mercedes-Benz AG

Mercedes-Benz is premiering its new MBUX (Mercedes-Benz User Experience) multimedia interface, which will debut in the upcoming EQS battery electric sedan. Dubbed MBUX Hyperscreen, the digital experience promises to transform how we interact with the vehicle, and provide a “wow” effect according to Mercedes-Benz.

The marketing video (below), was almost like one which you might expect from Apple or Samsung, with the carmaker spruiking the technical specs of the computing power behind the new in car system. With 8 CPU cores, 24-gigabytes (GB) of RAM and 46.4 GB per second RAM memory bandwidth, Mercedes-Benz is promising a next-generation infotainment system that delivers an intuitive experience, and actually learns driver behavior.

According to Gorden Wagener, Chief Design Officer Daimler Group, “We merge technology with design in a fascinating way that offers the customer unprecedented ease of use. We love simplicity, we have reached a new level of MBUX.”

Sajjad Khan, Member of the Board of Management of Mercedes-Benz AG and CTO states that the MBUX Hyperscreen continually gets to know the customer better through machine learning, and delivers a personalised infotainment and operating offering before the driver has to even access or scroll through menus.

With context sensitive awareness, the MBUX system proactively displays the right functions at the right time for the user, supported by artificial intelligence. The system is optimised by changes in the surroundings and user behaviour. The so-called zero-layer provides the user at the top level of the MBUX information architecture with dynamic, aggregated content from the entire MBUX system and related services; deep menu layers — a criticism of complex current generation infotainment systems — are a thing of the past.

Mercedes-Benz provides these four examples as use cases:

The user can accept or reject the respective suggestion with just one click:

If you always call a certain friend on the way home on Tuesday evenings, you will be asked to make a corresponding call on that day of the week and at this time of day. A business card with its contact information appears, and - if stored - its image appears. All MBUX suggestions are linked to the user's profile. If someone else drives the EQS on a Tuesday night, this recommendation is not made – or there is another, depending on the preferences of the other user.

If the EQS driver regularly uses the massage function according to the hot stone principle in winter, the system learns and automatically suggests the comfort function in wintry temperatures.

If the user regularly switches on the heating of the steering wheel and other surfaces for seat heating, for example, this is suggested to him as soon as he presses the seat heating.

The chassis of the EQS can be lifted to provide more ground clearance. A useful function for steep garage entrances or sleep policemen. MBUX remembers the GPS position at which the user made use of the "Vehicle Lift-Up" function. If the vehicle approaches the GPS position again, MBUX independently proposes to lift the EQS.

In terms of design, Mercedes-Benz has integrated ambient lighting behind the glass, making the display unit appear to float on the seamless instrument panel. There is also a separate passenger display, a-la Porsche Taycan. If no passenger is seated, the display becomes an animated decorative pattern of stars, so as not to distract the driver with additional infotainment content.

Central and passenger displays utilise OLED technology, where non-active pixels remain switched off, meaning that they appear as deep black rather than a greyish black that is visible on many computer monitors. With a multifunction camera and light sensor to adjust the brightness of the display and pre-empt driver actions, it’s expected that the EQS’ active and passive safety systems will work seamlessly with the MBUX Hyperscreen.

It appears the MBUX Hyperscreen takes the best of the 2021 Mercedes-Benz S-Class infotainment system, and builds upon it, seamlessly integrating multiple displays into a single panel. It’s a distinctly different approach from other EV manufacturers such as Telsa, who prefer to combine all features into a single, centrally-mounted touchscreen. Mercedes-Benz spends billions on R&D and probably millions determining customer preferences, so it’s likely their customers still prefer something akin to a traditional instrument cluster.

While the Mercedes-Benz system provides haptic touch feedback, There’s much criticism about the trend to remove all buttons from a vehicle’s interior. While we think it’s great to seamlessly integrate all system functions into one unit, presumably minimising cost and improving reliability, if that comes at a cost — the ease of quickly operating essential controls — then its not worth it. We hope Mercedes’ “zero-layer technology” and voice control systems can make basic actions like adjusting the climate control temperature or re-routing a navigation destination quick and painless, but we’ll have to wait until the vehicle’s reveal for more information. Mercedes-Benz will reveal the EQA SUV on January 20, and we think the EQS should break cover sometime in the first quarter of 2021.